2010-DEC -> Cabin Complex Renovation Project Status for 2010

|

2010 is our year to finish our Cabin Complex Renovation Project that began in earnest last April (see 2009 Monthly Archive). These additions, when complete, will transform our property into a fully-functioning, year-round, business event and agri-tourism destination. More details to follow. . . (continue to check back each month and see our progress reports)[Progress Photos below taken January 31, 2010]

Tim Hanauer prepared an overall farm plan for us when we purchased the property in 1997. We asked him to return and provide us with more detail for the Cabin complex area. His ideas have improved upon our vision for the future use and adaptability of our farm property. We would highly recommend that such an expert be retained for their professional advice.

The photo to the right shows 10 cubic yards of course rock screening fill material that will be used to begin grading areas adjacent to the Cabin. Weather during the month of February has once again curtailed our ability to make significant progress. We are about to complete a comprehensive review of our farm insurance policies (long overdue). Much site debris was removed to the county landfill. Other needed supplies have been stockpiled. When the weather breaks, we will be poised to make significant progress. We have received questions about our Italian Rustic Pizza/Bread Oven plans. We are building a custom Italian “forno” or masonry beehive-like, hardwood-fired oven with over a 4-foot inside diameter. We will be baking artisan breads, pizza and roasts. Temperatures up to 800-deg-F can be attained. More to follow – stay tuned. Progress Photos below taken March 31, 2010 A view from the other side of the basement-level patio. The septic tanks are now hidden underground. Stone steps remain to be positioned to provide walking trail access from the patio to Lynch Creek in the ravine. Another view of the Wood-fired Oven patio area in front of the Cabin. Only a portion of the patio has been rough graded near the oven counter wall. Concrete footings for Stone Seating Walls that define the Patio remain to be dug, formed and cast. The outdoor Fireplace will also double as a serving surface when not in use.

This slab, the oven slab and the stone wall footings will be cast at the same time in April. Now that the weather has begun to improve, progress with the remaining outdoor work should accelerate. Estimates are being secured to complete the indoor plumbing and electrical work. We are behind schedule, but given the challenges posed by the wet and cold winter weather we have experienced this year, we still are optimistic that we can complete construction in 2010. Progress Photos below taken April 30, 2010 We moved boulders, topsoil, and installed timber steps to complete the landscaping of the southern side of the Cabin. Natural plantings will be installed next month. This provides a walking trail to the lower level and will “hide” the HVAC equipment that will be installed this fall.

A tremendous amount of work has been completed in April. The weather has begun to cooperate. Next month we expect to complete: the outside landscaping of the Cabin (front and north side); the Parking area grading and seeding; the footings for over 70′ of additional seating walls. Stone seating wall construction may also begin. We hope to move construction of our Brick Oven along: cast the insulating concrete atop the structural slab shown in the photo above; remove all temporary supporting formwork; and begin laying fire brick (floor and circular courses) for the Oven. We expect to complete the installation of the rough oak patio Serving Counter. We are awaiting plumbing and electrical estimates for the Cabin Interior. We hope to have our outdoor dining area fully functional by September (if not sooner). The Cabin interior completion is still targeted for year-end. Check back next month and see the progress we have made. More details and photos to follow. Progress Photos below taken May 31, 2010

The photo to the right shows a custom tool made to precisely lay circular courses of brick. The inside Oven diameter is 56″. Notice the herringbone pattern used for the Oven floor.

The main Patio area is taking shape with the completion of 50′ of stone seating wall with a typical height of 18″ when final graded with accompanying landscaping. See the adjacent photo to see a close-up of the wall detail. Significant progress will be made on the Oven construction in June. Additionally this month, all outside caulking of the Cabin windows was completed, together with the installation of fascia boards at the Cabin roof. The second floor interior roofline was sealed along the perimeter in readiness for insulation work once the plumbing and electrical work in completed. Significant soil and mulch was moved in place around the Cabin foundation and behind all of the new stone walls. It seems certain that the exterior spaces will be completed and fully functional in September. b.t.w. Bridge construction commenced on June 1st – Rocky Ford Road is now closed – access to Lynch Creek Farm is only coming east from Bobbitt on Rocky Ford Road – we have been informed that the bridge will be completed by September 1st (hopefully). Stay tuned for monthly updates until we complete this project. Progress Photos below taken June 30, 2010

Much landscaping work has been completed – backfilling walls, grading, steps, leveling, walkways and placing plant materials. Watering during June has been daily due to the lack of rainfall and high temperatures.

The month of June (despite being the hot-est and dry-est on record) was very productive. Due to the shade in the Cabin area outside work progressed steadily. The final “look” of the area is taking form. Progress at times seems slow, but the photo-history of the project has documented the incremental nature of the work. Our vision and plan for the outdoor space is finally being realized. We are anxious to get it done. F.Y.I. The Cabin complex will also serve as the “home” for they Ben Franklin Society of Franklin County (which Bob initiated in 2008) and which is now a qualified, 501(c)(3), non-profit corporation dedicated to fostering “Independent and Collaborative Research on matters of importance to Franklin County, NC” Stayed tuned each month as we approach completion this year. Progress Photos below taken July 31, 2010

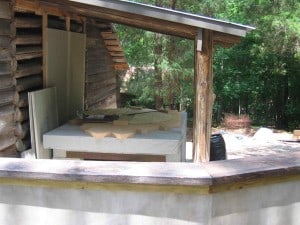

The Shed door has been enlarged and siding boards added to “waterproof” the interior storage space. This construction technique will be used to “cover” logs near the Wood-fired Oven and for the Smokehouse building.

Most effort this month has been to survive the drought and heat. July was the second hottest on record. It is expected that steady progress will be made during August. We hope to have an Open House Event late-September – to celebrate completion of the Outdoor Dining Area, the opening of the new Rocky Ford Road Bridge, promotion of the Ben Franklin Society and details about the BreadWorks – stay tuned for details in our August progress posting. Progress Photos below taken August 31, 2010

Scaffolding was erected alongside the Cabin chimney to permit: (1) an HDTV Antenna to be installed (with grounding wire); (2) to accomodate a Wi-Ex cell phone booster antenna; and (3) to permit final stone pointing of the “chase” along the chimney to be completed. The “long range” antenna with rotor will pickup all free OTA (Over-the-Air) HDTV available frequencies. The cell phone booster will create a “cell reception/transmission zone” inside the Cabin that supports all carriers and simultaneous users. This is required to provide reliable cell service for our business meeting clients.

A new boulder wall was constructed (yet to be final graded) with appropriate drainage). This area is contiguous with the lower level patio, and will form a level overflow patio area capable of accomodating a 20’x20′ party tent (if needed).

The outdoor landscaping is near completion. Only low voltage lighting fixtures remain to be installed. The Driveway and parking area will be final graded shortly. While we will continue to add plant materials in the Fall, the overall terrain contouring is finally complete – quite a task given the slopes that surround the Cabin itself. Come see for yourself! Additional interior rough-in plumbing has been completed and is nearly finished. Electrical rough-in begins in September. Our planned Labor Day celebration event has been delayed because the Rocky Ford Road Bridge completion is not expected until later in September. Stay tuned for our party details, once we are confident of a bridge re-opening date. Progress Photos below taken September 30, 2010

Free OTA (Over-The-Air) HDTV support for about 25 channels is now supported on each of the three Cabin floors (basement, main and loft). The antenna rotor allows the long range antenna to be positioned directly at several TV transmission antennas in a 65 mile service radius. The Wi-Ex Cell-phone Booster system creates a “cell zone” within the Cabin and provides excellent cell phone reception from multiple service providers to an unlimited number of simultaneous cell phone users. Normally, reception at our remote farm location is “spotty”. With this technology, cell-phone reception is no longer a problem for casual and business use. The driveway and cabin parking areas have been final graded by Faulkner Grading and Landscaping of Henderson, NC. Top soil has been added to the parking area, then fertilized and seeded to establish sod grass this fall. Notice the electrical contractor work trailer in the photo.

The new lower patio area has been final graded as shown below. This area provides a great view of Lynch Creek in the ravine below and lets you hear the running water year-round. The completion of this patio more importantly solves a huge site drainage problem by as well serving as a “sink” for excess water from the entire Cabin Complex. When you visit – you will see what I mean.

Some other significant tasks completed during September included: 1) the spray waterproofing of the outside cabin logs – necessary every 2-3 years; 2) the addition of earth “ground-cover” berms along the driveway in front of the Cabin; 3) The removal of a 50′ sweet gum tree that extended precariously over the Shed building housing our Wood-fired Oven; 4) the rough-in electrical work at the Cabin basement level; 5) additional landscape materials were planted throughout the Cabin Complex; 6) prep work was completed to support the transfer of our Lynch Creek telephone service (252-492-2600) to the Cabin; and 7) arrangements were made to have blacksmith Paul Gove add decorative work to our metal Oven Door. It has been a busy month. Much progress has been made. We are rapidly transitioning from emphasis on outside work tasks to those inside the cabin as the seasons change from summer to fall and winter. Stay tuned to see what we get done next. Progress Photos below taken October 31, 2010

The photo to the right shows additional boulders added near the entrance gate to diffuse all site drainage water that flows to the stream under our driveway (that eventually drains into Lynch Creek).

Inside the cabin, additional electrical and carpentry work (drop ceiling in basement bathroom) has been completed at the basement level. Preparations are being made for a rough-in inspection that will permit close-in to proceed. Additional landscape materials have been planted (dogwood trees, spring bulbs) in our final push before winter sets in and freezing temperatures begin.

The photo on the left shows the Oven entrance has been cast and the counter concrete wall has been stained. The concrete used is special (metal-casting mix) to withstand the high oven temperatures. The photo on the right shows two brick courses of the oven have been set. All brickwork must be completed before the ambient air temperatures drops below freezing. Notice that on the inside-face of the oven, bricks are laid flush (without mortar joints). Special mortar (Super#3000) is also used that withstands temperatures in excess of 1000-deg-F. When completed the oven will be a circular dome with a 56″ inside diameter. The outer surface of the bricks must later be coated with a fireclay mixture and 2″ of insulating concrete to further insulate and help contain the heat inside the Oven. The exterior finished surface of the dome has been designed to only reach 100-deg-F. As a side-light, we have been researching restaurants that have wood-fired ovens. We recently visited Bella Mia in Cary, NC that has “Authentic Coal Fired Pizza” to find that they actually use a mix of coal and wood that moderates the high coal temperatures (1000-deg-F) in the oven with wood that heats to 800-deg-F. It is these high temperatures that create the “crust” on pizza that I remember as a child from our local Italian neighborhood “Tomato Pie” bakery. So expect to see our Oven be both wood- and coal-fired and find Tomato Pie on the menu. We have chosen to have blacksmith Raymond Mathis ( www.tuttometaldesign.com ) from Doylestown, PA embellish our Oven Door – reaching back to our roots in Pennsylvania. Although not large (roughly 12″ x 20″) we want it to become a piece of art, not just a functional metal door. Appropriately, on Sunday, October 10th we held the first Ben Franklin Society meeting on the Cabin Grounds. Sadly we forgot to take photos, but the event was spectacular – great folks, food and weather! The “Franklin BreadWorks” project was approved by the membership – a private (member only) dining club at Lynch Creek Farm. Hopefully next month will nearly complete the Oven project. Once all masonry work is complete, the Oven must be “dried-out” with the daily burning of successively hotter fires over a 7-day period. This process of “curing” the Oven ensures that we do not crack the masonry with rapidly expanding moisture (steam). After the “break-in”, we can begin cooking. My, it’s been over two years since I embarked on this project. I must say, much shorter than the Cabin project which is now over eight years in the making. Progress Photos below taken November 30, 2010

In the photo below you can see the difficulty of running electrical conduit in an authentic log cabin. Unlike modern pre-fab cabins built from manufactured logs, there are no pre-drilled conduits for running electrical cables with a “real log building”. Since we will “chink” all interior log surfaces (like that on the outside), the wiring must be hidden and foam insulation applied beforehand. The Cabin service entrance has been leveled and surfaced as shown in the photo on the right.

Most importantly, we have passed our next-to-last Franklin County building inspection in November. Additionally we have added plant materials along the driveway fence-line and recently completed parking area. Our friend, Joe Elmore, allowed us to transplant native rhododendron and azaleas around the Cabin complex from his property in Mapleville, NC.

The photo on the left is a view looking into the Oven entranceway. The reveal edge seals the Oven when the Oven door is used for baking bread (or any other oven-cooked meal). Notice the atypical flue located on the entrance ceiling outside of the Oven itself, not inside. After the Oven is fired with oak and coal, a small fire will remain burning on the right side of the Oven, while all Tomato Pies (a.k.a. Pizza) are cooked (without using the Oven door) on the left hand side. All Bread and Tomato Pies are cooked directly on the brick oven floor. In the photo, a sheet of plywood is temporarily there to protect the oven floor bricks during construction of the dome and to center the brick radius tool that guides the dome shape – one brick at-a-time. The photo on the right shows how the half-brick segments are staggered to overlap all joints and tilted to maintain the needed curvature. I now fully understand why these Ovens are now sold as prefab kits. I have saved a considerable amount of money at the expense of a lot of time on my part; however, it has been satisfying to meet the technical and fabrication challenges involved. Our Oven Door is being fabricated by Ray Mathis as mentioned in last month’s progress report (hence, no Oven Door is shown in the pictures above). I take great pride in the workmanship I have contributed to this functional, yet unique addition to our Lynch Creek Farm property. I believe folks will always be fascinated to look in the Oven as food is baked and marvel at the open fire and ambiance of our outdoor picnic area. When you come visit next year, tell us about your reaction to the experience of dining at the Franklin BreadWorks. As an aside, Kerry and I have been fine tuning our Artisan Bread-making skills. On March 20, 2010 we attended the Asheville Artisan Bread Festival in Asheville, NC and a cooking seminar by renowned Artisan Bread Baker, Peter Reinhart (James Beard award-winning author of The Bread Bakers Apprentice). We also took a hands-on seminar with noted French Master Baker, Lionel Vatinet of the La Farm Bakery in Cary, NC on November 2, 2010. We have been producing test loafs of bread (including natural-yeast Sourdoughs) all year. We also have begun to experiment with making Cheese – whole-milk Mozzarella variations have done well. I am finally getting to use my culinary skills from my restaurant days in Philadelphia – over thirteen years ago now – ouch! Stay tuned. The Cabin and Oven will be ready for use early next Spring. All remaining interior work will be completed this Winter in the comfort of a heated Cabin. Finally I can see the end in clear sight. This phase of our journey is nearly complete. We will be able to share the next phase with our family, friends and future visitors. Progress Photos below taken December 31, 2010 The coldest December weather ever in North Carolina stymied our efforts to complete the masonry work on the Wood-fired Oven. With temperatures below freezing (over 20-deg-F below normal on a daily basis) all masonry work had to cease. All work this month was indoors.

Inside the Cabin itself, the electrical wiring is nearly completed. Additional framing and prep-work was performed on both bathrooms and the kitchen. Tiled, walk-in showers have been prepped and plumbed. Outside lighting and deck fans have been installed. All interior electrical and plumbing work will be completed in January 2011. Hopefully the weather will moderate to permit Oven masonry work to resume. Between the weather, holiday activities and some illness in December, progress was slowed, but we still expect to be fully operational by Spring of 2011.

|

Leave a Reply